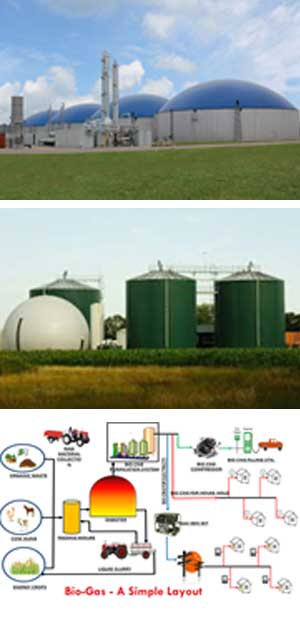

ELAMIUAN METANO ENERGIA SUSTAINABLE SERVICES understand biogas technology in its entirety: the optimal interaction of individual processes determines the economic success of your biogas plant. The competence for planning, approval, plant construction, technical plant service and CHP service as well as connected with associated laboratory for biological service and process optimization make Planet a special brand for biogas and biogas technology.

We provide professional End to End Solutions in Waste Management, Waste to Energy and Energy Distribution. We install biogas digesters, As an integrated technology company, has expertise in Design, Supply and Installation of Biogas plants for varying applications ranging from Household Cooking to Industrial Cogeneration purposes including Power Generation and Bio-CNG Bottling plants.

We have to got an inquiries from Mother Dairy, Pharmaceutical factories, wheel axle plant, Indian Navy, ISRO, Automotive Axles Limited, Hotels, Hospitals, We also supply domestic Biogas plants of varied sizes. We have got connected with Indian and European bonafide vendors in this sector.

In order to stay a technology leader we work closely with research institutes. Our Technology partners are from Sweden, Netherlands, Germany, Belgium, Austria.

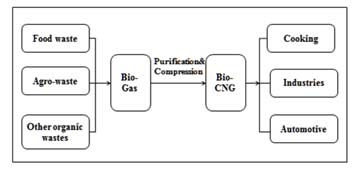

Bio compressed Natural Gas ( BioCNG)

As fossil fuel resources are finite and are among the biggest contributors to climate change, it is critical that we meet our energy needs from renewable resources. India’s renewable energy resource potential is significant, with solar, wind, biomass, and small hydropower representing the technologies having the largest potential. Among all, biomass warrants special attention. All the living matter present on earth derived from growing plants including algae, trees, and crops or from animal manure is called biomass.

In India traditionally biomass had been utilised either through direct combustion or anaerobic digestion. Anaerobic digestion of biomass is the process in which organic matter, in the absence of oxygen, is mainly transformed into a mixture of methane and carbon dioxide which is usually referred to as biogas.

BioGas to BioCNG

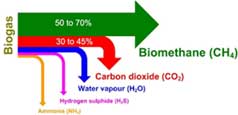

Biogas consists mainly of methane (CH4, 55-65%) and carbon dioxide (CO2, 35-45%) and the calorific value of biogas is ~19500 KJ/Kg. Methane is a valuable form of gas, as it is an efficient energy carrier with a wide range of uses. The amount of CO2 that is produced corresponds to the amount of CO2 captured when the biomass was created, making biogas carbon neutral.

- Biogas is a mixture of different gases produced by the breakdown of agricultural waste, manure, municipal waste, plant material, sewage, green waste, or food waste, in the absence of oxygen. When this mixture is further purified and processed, it is called bio-compressed natural gas (bio-CNG). It is similar to natural gas in terms of its composition and properties, and is a cleaner alternative to fuels such as petrol and diesel.

- In India, bio-CNG has immense scope, specifically as a replacement for the more widely used CNG and liquefied petroleum gas (LPG). Besides, bio-CNG can cater to diverse segments of the market with applications in commercial (hotels, canteens, bakeries and resorts), industrial (glass and ceramic, metal processes, cement and textiles) and automotive (public transport and private vehicles) processes.

- Apart from replacing CNG and LPG, bio-CNG can be used in lieu of biogas, which has an estimated market potential of 1,281 MW. For instance, distilleries, and sugar and starch factories meet about 75 per cent of their energy needs through biogas, and thus could be the potential consumers of bio-CNG as well. Other industries like milk processing, pulp and paper, and slaughterhouses could also utilise bio-CNG to meet their energy needs.

- Aside from methane and CO2, biogas also contains trace components like water vapor, hydrogen sulfide (H2S), siloxanes, hydrocarbons, ammonia, oxygen, carbon monoxide, and nitrogen.

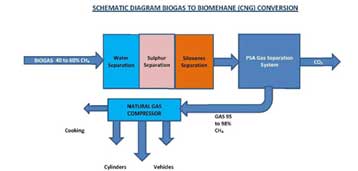

- Bio-CNG is produced from biogas, through a simple and convenient process involving desulphurisation, upgradation and compression. First, biogas is desulphurised, if the hydrogen sulphide content is over 1,500 ppm. Then, the desulphurised biogas is upgraded to make its composition similar to CNG, followed by the compression and bottling of the resulting bio-CNG.

- Bio-CNG contains about 92-98 per cent methane and only 2-8 per cent carbon dioxide, while biogas contains 55-65 per cent methane with 35-45 per cent carbon dioxide. The calorific value of bio-CNG is about 52,000 kilojoules (kJ) per kg, which is nearly 167 per cent higher than that of biogas at 19,500 kJ per kg.

The high methane content and calorific value combined with the low quantity of moisture, hydrogen sulphide and impurities makes bio-CNG an ideal fuel for automobiles and power generation. The low emission levels of bio-CNG also make it a more environment-friendly fuel than biogas

Sustainable Resource Management

- Biogas Technologies

- Waste to Biogas

- H2s Scrubbers

- Zero Liquid Discharge Technologies (ZLD)

- Zero Chemical Treatment (ZCT)